Hazelnut is the fruit of the Lombard nut. The fruit is covered with a hard shell and the kernel is about half the weight. The shrub can grow up to 10 meters in height. Hazelnuts begin to bloom in early spring, and the first nuts appear on it in early autumn.

This nut was known back in the days of Ancient Greece. Hazelnuts are considered to be one of the most delicious and aromatic nuts. Hazelnuts are very nutritious and are considered a “calorie bomb” – their energy value surpasses even chocolate. Therefore, a handful of hazelnuts can replenish the supply of strength for a long time. It is often eaten by athletes and people engaged in active physical work.

Hazelnut contains up to 60% fatty oils, which consist of glycerides of oleic, stearic and palmitic acids. They protect and strengthen blood vessels, and are also important during the stage of active growth.

There are a lot of vitamins B1, B2, C, E in hazelnuts, as well as minerals: potassium, iron, cobalt, phosphorus, calcium, zinc. These connections are necessary for the normal functioning of all systems and organs.

Hazelnuts are allowed to be eaten by patients with diabetes due to their low glycemic index. At the same time, the use of nuts will reduce the risk of vascular complications.

AZERBAIJAN HAS ALL THE NECESSARY WEATHER AND CLIMATIC CONDITIONS FOR GROWING HAZELNUTS. PLANTING AND THE NUMBER OF NEW GARDENS IS INCREASING BY AN AVERAGE OF 4-5% ANNUALLY.

At present, Azerbaijan is among the five leading producers and exporters of hazelnuts, along with Turkey, Georgia, Italy and the United States. According to International Nut & Dried Fruit, Azerbaijan owns 4% of the world hazelnut production market.

The following varieties of hazelnuts are grown in Azerbaijan: Atababa, Ashrafli, Galib, Ganja, Khachmaz, Sachagly, Topgara and Yagly.

The most common varieties are Ata-baba and Khachmaz.

Founded in 2017, the hazelnut processing plant is equipped with modern processing and packaging equipment. Production capacity is 3 tons per hour of hazelnuts or 1.1 tons per hour of kernel.

The roasting and crushing workshop produces hazelnuts with the necessary humidity level in 3 different calibers.

The products are mainly exported to EU countries, in particular to Italy and Germany.

The plant is also equipped with a modern ventilation system, which provides a comfortable working environment as well consistent product quality. Besides the standard products, the plant also produces bio-organic products in a specially

separated and certified line.

The production process is divided into 5 stages:

• Reception – cleaning and weighing

• Drying – the product is dried using the regulator humidity

• Sorting – the process of screening out and calibrating

• Sampling and purification – quality control process

• Packaging – vacuum and regular packaging in polypropylene bags

All stages of production take place under careful control where product quality and moisture level continuously tested by the laboratory. All products manufactured in accordance with EU quality standards.

UNPEELED HAZELNUTS (in shell)

Caliber: 16, 17, 18, 19, 20, 21+

Packaging: jute or polypropylene bags.

Application: Natural or fried, with or without salt, as a snack

PEELED RAW HAZELNUTS (without shell)

Caliber: 19-11, 11-13, 13-15, 15+

Packaging: jute or polypropylene bags,

vacuum packaging, Big Bags

Application: Natural or fried,

with or without salt, as a snack

BLANCHED HAZELNUTS

Caliber: 9-11, 11-13, 13-15, 15+

Packaging: jute or polypropylene bags, vacuum packaging

Application: as a snack, in cooking to add aroma and taste to various dishes, in confectionery when preparing sweets, in chocolate bars

SLICED HAZELNUTS

Caliber: 1-5+

Packaging: jute or polypropylene bags, vacuum packaging

Application: as an appetizer, in cooking to add aroma and taste to various dishes, in confectionery as decoration.

BASIC QUALITY INDICATORS:

PHYSICAL AND CHEMICAL INDICATORS

MICROBIOLOGICAL INDICATORS

JUTE BAG

Weight: 50 kg.

VACUUM PACKAGING

Weight: 5/10/20/25 kg

+ is additionally packed in a cardboard box

PP BAGS (Polypropylene)

Weight: 25/40/50 kg

BIG BAG

Weight: 1000 kg

Standard markings: name, caliber, crop, manufacturer, country of origin, weight, batch, term suitability.

Expiration date: 12 months.

ГРАНАТОВЫЙ КОНЦЕНТРАТ 65 Brix

Гранатовый концентрат 65 Brix в асептических мешках (розлив неасептический) в бочках по 250 кг. Производственный процесс проходит c соблюдением высоких требований качества в соответсвии ISO 22000 FSMS.

ГРАНАТОВЫЙ СОК ПРЯМОГО ОТЖИМА

Мы предлагаем 2 вида гранатового сока прямого отжима: неосветленный гранатовый сок, осветленный гранатовый сок или фильтрованный с минимальным фруктовым осадком в асептической упаковке уложенный в металлическую бочку с нетто весом 220 кг. или в стеклянной бутылке, обьем 1.0 л и 0.25 л.

ГРАНАТОВЫЙ СОУС НАРШАРАБ

(в стеклянной бутылке 250 мл.)

Гранатовый соус Наршараб это многолетняя традиция Азербайджана. Обладает пикантным, приятным, гармоничным вкусом. Гранатовый соус Наршараб варится из сока кислых садовых и диких сортов граната, которые и формируют его пикантный кисло-гранатовый вкус. Он является идеальным дополнением, как для мясных, так и для рыбных блюд.

Его можно использовать в качестве маринада и заправки для салата.

ГРАНАТОВЫЙ ФРУКТ

В основном мы выращиваем сорта граната Гюлейша и Мина Ширин.

Что нас отличает от других поставщиков.

– Наши фрукты обладают уникальным вкусовыми качествами, так как мы культивировали наши сорта гранатовых плодов на протяжении последних 12 лет

– Наши фрукты обладают уникальным вкусовыми качествами, так как мы культивировали наши сорта гранатовых плодов на протяжении последних 12 лет

– Наши сады – это сады интенсивного плодоношения с применением современных агротехнологических методов. Это в свою очередь дает возможность выращивать не только вкусный гранат, но и получать красивый и привлекательный товарный вид с ярким красно-рубиновым цветом без всяких пятен и трещин.

– После сбора урожая мы проводим ручную калибровку фруктов, гарантируя стандартный размер фруктов в упаковке и ее соответствие этикетке. Мы предлагаем  2 вида размеров фруктов: а) калибр 90+ в) калибр 100+

2 вида размеров фруктов: а) калибр 90+ в) калибр 100+

– Вся наша продукция упаковывается в специальные модифицированные атмосферные упаковки (МАР), что обеспечивает сохранность фруктов на протяжении долгого периода времени. Также фрукты укладываются в ячейки, что гарантирует сохранность при транспортировке и перемещении упаковки. Продукция упаковывается в картонную упаковку или пластмассовые тары.

– Первый урожай начинается с 20 сентября и продолжается до конца октября. С ноября до февраля возможна продажа со складов.

Founded in 2017, the hazelnut processing plant is equipped with modern processing and packaging equipment. Production capacity is 3 tons per hour of hazelnuts or 1.1 tons per hour of kernel.

The roasting and crushing workshop produces hazelnuts with the necessary humidity level in 3 different calibers.

The products are mainly exported to EU countries, in particular to Italy and Germany.

The plant is also equipped with a modern ventilation system, which provides a comfortable working environment as well consistent product quality. Besides the standard products, the plant also produces bio-organic products in a specially

separated and certified line.

The production process is divided into 5 stages:

• Reception – cleaning and weighing

• Drying – the product is dried using the regulator humidity

• Sorting – the process of screening out and calibrating

• Sampling and purification – quality control process

• Packaging – vacuum and regular packaging in polypropylene bags

All stages of production take place under careful control where product quality and moisture level continuously tested by the laboratory. All products manufactured in accordance with EU quality standards.

JUTE BAG

Weight: 50 kg.

VACUUM PACKAGING

Weight: 5/10/20/25 kg

+ is additionally packed in a cardboard box

PP BAGS (Polypropylene)

Weight: 25/40/50 kg

BIG BAG

Weight: 1000 kg

Standard markings: name, caliber, crop, manufacturer, country of origin, weight, batch, term suitability.

Expiration date: 12 months.

BASIC QUALITY INDICATORS:

PHYSICAL AND CHEMICAL INDICATORS

MICROBIOLOGICAL INDICATORS

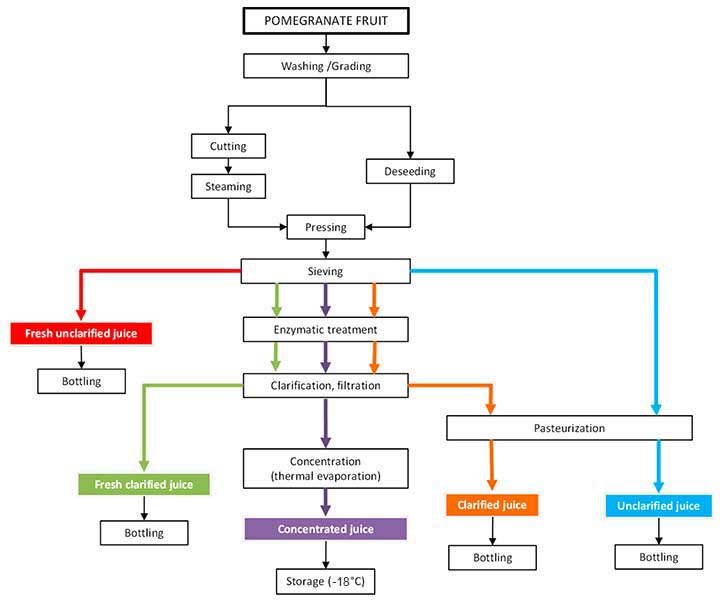

The production process begins with the acceptance of fruits, washing, and after the selection of offgrade fruits, the process of separating the peel from the pomegranate seeds begins. Then the seeds are compressed on a belt press and the resulting juice is sieved. In the next stage, to obtain clarified juice it passes via the process of filtration and then roasting. During unclarified juice production after sieving the juice is filled in aseptic bags and placed in metal barrels or pasteurized and bottled.

In the production of pomegranate juice concentrate for unclarified products after sieving, and for clarified products after filtration the juice is evaporated (evaporation process), where its dry matter increases from 15-16 Brix to 65 Brix. Then as the final product pomegranate juice concentrate is filled in aseptic bags and placed in metal drums. Pomegranate juice concentrate should be stored at a temperature of – 18 °C.

No preservatives, sugar or dyes are used in production. The entire production process is carried out in compliance with the highest requirements and quality standards such as ISO 22000 FSMS.

POMEGRANATE JUICE CONCENTRATE SPECIFICATION

Description: Concentrate Pomegranate Juice is exclusively manufactured from fresh, mature, unfermented pomegranates under FSSC regulations. The product does not contain any additives, sugars, allergens, genetically modified organisms or any undesired substances.

Ingredients: Concentrated Pomegranate Juice

Colour : Red viscous liquid

Flavor: Distinct good pomegranate flavor. Free from undesirable flavors, traces of scorching, caramelization and oxidation.

Aroma : Typical of fresh pomegranates. Free from foreign odors.

Brix : 65 ± 1

Acidity: 6.0 – 7.8 % (as citric acid, anhydride)

PH: < 4.4

Brown ratio 520nm/430nm: min 1

NTU: < 50

Packing: 250 kg aseptic bags (non-aseptic filling, bags placed in drums)

Storage temperature: – 18 °C

No additive, clear, without preservatives

POMEGRANATE CLOUDY JUICE SPECIFICATION

Description: Pomegranate Juice is exclusively manufactured from fresh, mature, unfermented pomegranates under FSSC regulations. The product does not contain any additives, sugars, allergens, genetically modified organisms or any undesired substances.

Ingredients: Pomegranate Juice

Colour: Red viscous liquid

Flavor: Distinct good pomegranate flavor. Free from undesirable flavors, traces of scorching, caramelization and oxidation.

Aroma: Typical of fresh pomegranates. Free from foreign odors.

Brix: min 14

Acidity: 1.2 – 1.7 % (as citric acid, anhydride)

PH: < 4.4

Brown ratio 520nm/430nm: min 1

NTU: ˃550

Packing: 200 kg aseptic bags (aseptic filling, bags placed in drums)

Storage temperature: +2 +4 °C

No additive, cloudy, without preservatives

POMEGRANATE JUICE SPECIFICATION

Description: Pomegranate Juice is exclusively manufactured from fresh, mature, unfermented pomegranates under FSSC regulations. The product does not contain any additives, sugars, allergens, genetically modified organisms or any undesired substances.

Ingredients: Pomegranate Juice

Colour: Red viscous liquid

Flavor: Distinct good pomegranate flavor. Free from undesirable flavors, traces of scorching, caramelization and oxidation.

Aroma: Typical of fresh pomegranates. Free from foreign odors.

Brix: min 14

Acidity: 1.2 – 1.7 % (as citric acid, anhydride)

PH: < 4.4

Brown ratio 520nm/430nm: min 1

NTU: < 50

Packing: 200 kg aseptic bags (aseptic filling, bags placed in drums)

Storage temperature: +2 +4 °C

No additive, clear, without preservatives

UNPEELED HAZELNUTS (in shell)

Caliber: 16, 17, 18, 19, 20, 21+

Packaging: jute or polypropylene bags.

Application: Natural or fried, with or without salt, as a snack

PEELED RAW HAZELNUTS (without shell)

Caliber: 19-11, 11-13, 13-15, 15+

Packaging: jute or polypropylene bags,

vacuum packaging, Big Bags

Application: Natural or fried,

with or without salt, as a snack

BLANCHED HAZELNUTS

Caliber: 9-11, 11-13, 13-15, 15+

Packaging: jute or polypropylene bags, vacuum packaging

Application: as a snack, in cooking to add aroma and taste to various dishes, in confectionery when preparing sweets, in chocolate bars

SLICED HAZELNUTS

Caliber: 1-5+

Packaging: jute or polypropylene bags, vacuum packaging

Application: as an appetizer, in cooking to add aroma and taste to various dishes, in confectionery as decoration.